Hopper bottom silos (also called cone bottom silos, hopper bottom storage bins, hopper bins) are the steel silos with a cone bottom. Hopper bottom silos are erected on the supporting structure to make the delicate products unloading easily through gravity. Hopper silos have a smooth wall hopper transition with no steps or flanges to offer the cleanest product discharge from the silo. The stored products inside the silo are isolated from the ground, thereby preventing humidity and allowing the interconnection of silos through tapes, facilitating perfect extraction or dosage.

The hopper, rings and support steel are made of hot-dip galvanized steel sheet. All our hopper cones for grain bins are designed in accordance D-4097 or ASTM D-3299 standards for elevated cone heads. According to the stored grain products and storing situations, the hopper or cone angles are commonly designed at 45º and 60º. The structure of hopper silo depends on the type of products to be stored. In generally, free flowing products pellet products like corn, wheat, soybean and feed pellets require the hopper bottom silo with a 45° angle while powder or other material which is hard to flow fits 60° cone bottom silo storage.Specifications of Hopper Bottom Silos

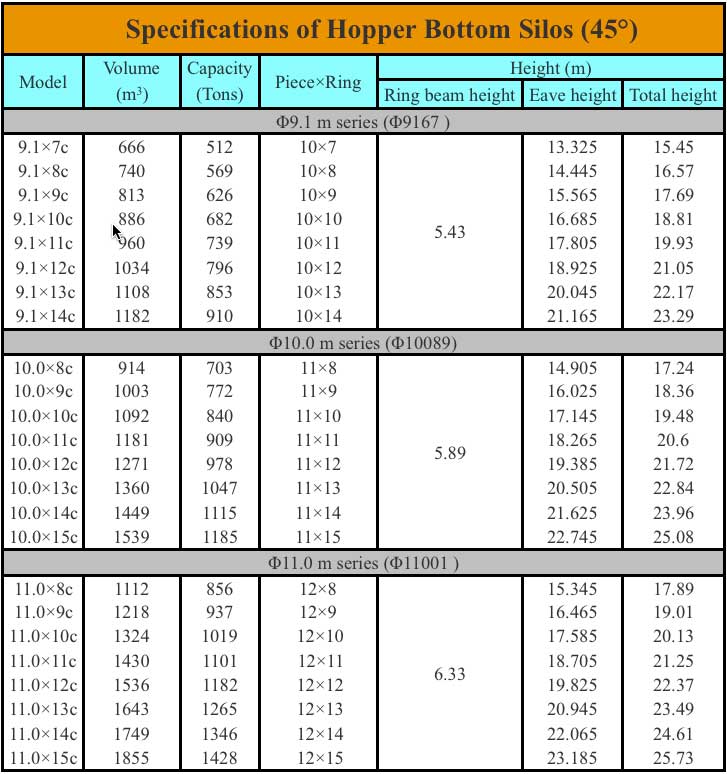

The volume of Shelley Brand hopper Bottom Storage Silo ranges from 20m³ to 1,875m³. The following is part of the specifications. Please click here to download more hopper silo specifications…

Main Components of Shelley Hopper Silos

hopper silo roof of Shelley Engineering

25º Sealed Roof

The special trapezoidal geometry of roof gives high strength and stiffness. The professional sealed technology enables tight connection of roof with the sidewall and keeps stored products from moisture.

Cylindrical Body

Shelley Brand hopper bottom silos are made with body sheets and stiffeners, manufactured with structural galvanized steel S350GD of high elastic tolerance and the coating equivalent to 600 g/m2 of zinc.

Galvanized Bottom

The cone bottom made with galvanized steel provides strength to support the silo and keep longer life span up to 28 years. 45º hopper is easy to unload delicate materials like feed pellets and other products.

Access Ladder & Door

Shelley Brand high-strength galvanized ladders have roll-formed sides and stamped rungs to eliminate rung spin for easily climbing. The access doors gives the second ring to access to the interior of the silo.

inspection door of hopper silos

Inspection Door

Shelley designs and installs the upper inspection door on the top of the steel silos to check the content and condition of the grain and treatments with a flexible cover for full protection of moisture and safety.

Storage grain silo(also called steel grain silo) is the efficient and economical facilities to handle grains, which can offer protection from outside insects and other affects as well as provide handling management conveniently.

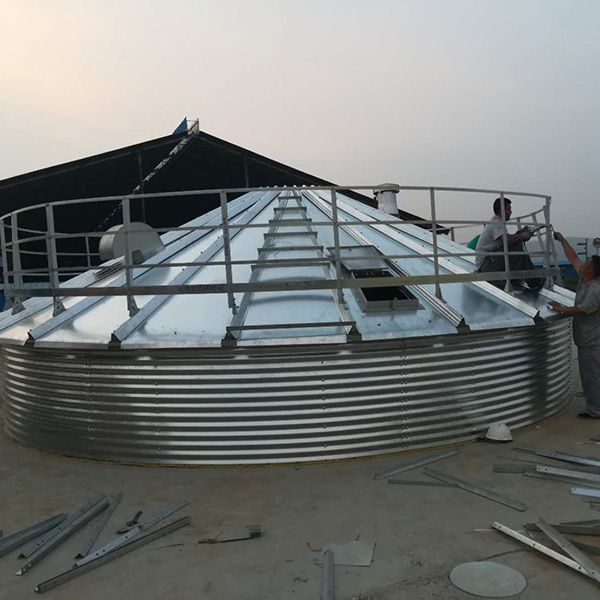

Storage grain silo(also called steel grain silo) is the efficient and economical facilities to handle grains, which can offer protection from outside insects and other affects as well as provide handling management conveniently. In this silo project,there are 4x500T flat bottom silos for corn and 2x150T hopper silos for soybean meals.The project in under installation now.

In this silo project,there are 4x500T flat bottom silos for corn and 2x150T hopper silos for soybean meals.The project in under installation now. Grain steel silo project is on the installation in Weifang city, Shandong province recently. The grain steel silo is used for corn storage, it also can be used for wheat, rice, paddy, barley, soybean and so on.

Grain steel silo project is on the installation in Weifang city, Shandong province recently. The grain steel silo is used for corn storage, it also can be used for wheat, rice, paddy, barley, soybean and so on.

Screenshot, wechat identification QR code

wechat number:WX:18653877118

(click wechat copy to add friends)